The Ice Co Storage & Logistics

Energy management system Ethos advises the Ico Co Storage & Logistics on £100,000 a year energy savings.

Star Technical Solutions have successfully introduced their ground breaking Ethos system into the Wakefield cold storage facility of The Ice Co Storage & Logistics to monitor, measure and analyse the performance of their refrigeration plant.

Using their refrigeration expertise, Star Technical Solutions have developed Ethos, a performance optimisation and energy management service for refrigeration equipment, to allow companies like The Ice Co Storage & Logistics to understand the energy consumption of different sections of their plant, alter plant settings to optimise that consumption and look out for, and anticipate, plant maintenance issues.

As part of the J Marr group of companies, The Ice Co Storage & Logistics is the leading manufacturer of quality ice and water products, temperature controlled storage and distribution, with brands that are internationally recognised as the product of choice.

Malcolm Dufton, The Ice Co Group Property and Energy Director said “We knew there were savings to be had but Ethos has allowed us to identify where those savings could be made and how. The result over £100,000 saving per annum on electricity, so now we are going to incorporate more plant into the network and roll out the program to our other plants and cold stores.”

Working on their knowledge of the plant gained from a maintenance agreement, Star were able to identify how best to deploy Ethos to deal with the most wasteful plant first which resulted in an energy consumption reduction of 33% and a consequent drop in emissions of 310 tonnes of CO2 per year. With The Ice Co they identified key areas where Ethos could improve their existing set up:

• Better information regarding performance and efficiency

• Improved operation of the whole plant to enable maximum energy savings

• Alerts when the system detects irregular patterns of behaviour of equipment and improved visibility of operating parameters.

The installation of Ethos consisted of a number of sensors connected to a central Ethos panel. The use of duplicate sensors minimised disruption to the existing operation as well as ensuring correct calibration and accuracy of the collected data. The panel incorporates a programmable logic controller (PLC), which relays the data collected to an SQL server. There is 4G connectivity built into the unit, and therefore there is no requirement for the system to be connected to the existing IT network. In turn, this reduces the workload involved in the installation.

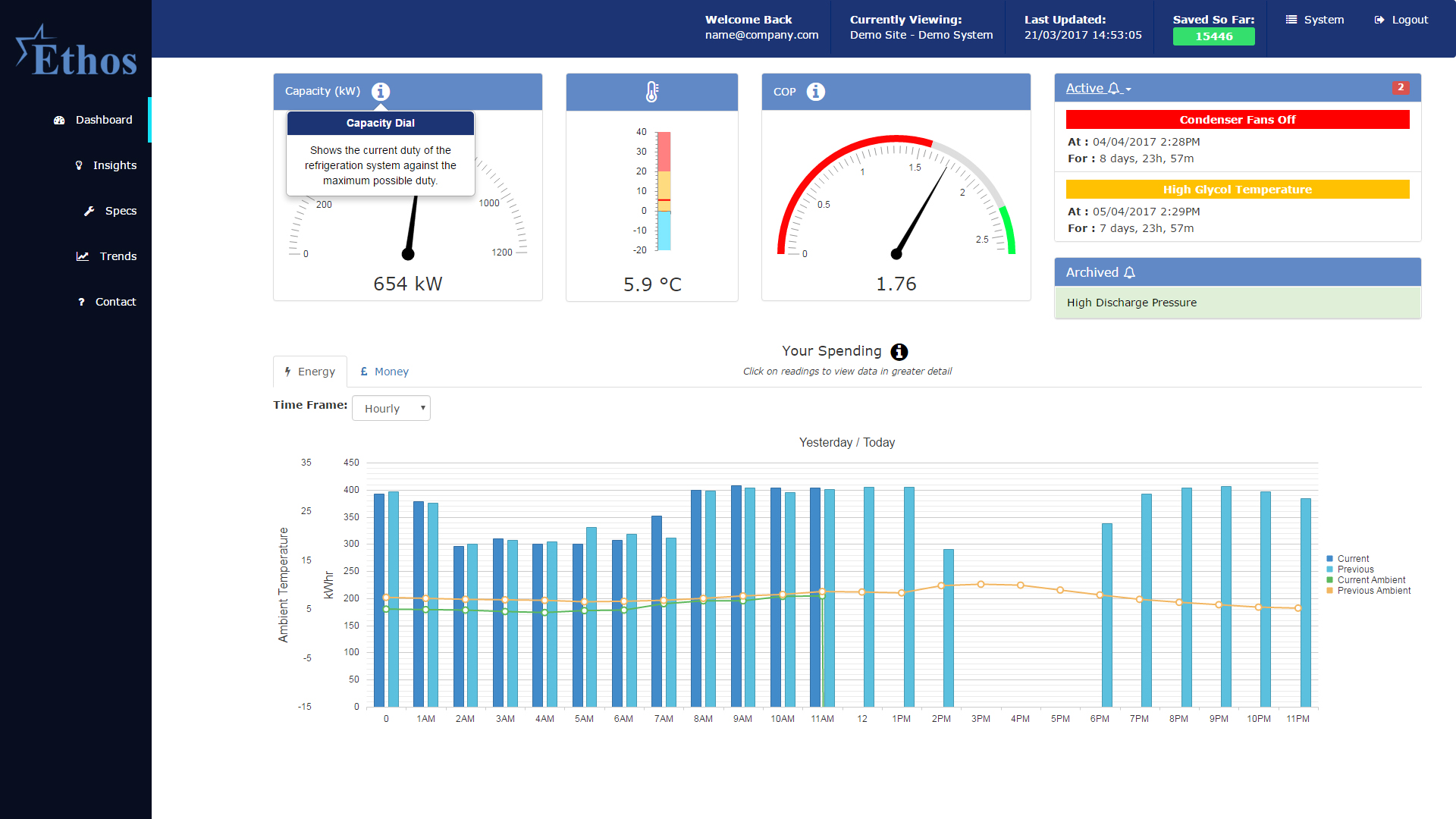

The information collected by the Ethos monitoring system is accessible in seconds via a comprehensive online dashboard, which can be viewed at any time and from anywhere on a smartphone, tablet or computer. This data visibility allowed The Ice Co Storage & Logistics access to an overview of their plant’s performance and to make energy-related savings in two distinct ways:

1) Targeted maintenance and simple control changes. The new system quickly identified that changes to condenser fan sequencing, condenser fan control, low-stage compressor sequencing and system purging would contribute to a cumulative energy saving of around 14%. The actions required to enact these changes were minimal or no cost.

2) Capital investment. Ethos was also capable of identifying areas where equipment upgrades or replacements could improve performance, thus justifying capital investment in new or existing technologies. For example, the compressor health check determined that the isentropic efficiency of one of the compressors was very low. Ethos was able to calculate that by replacing the compressor there would be an additional annual saving of around 24%.

From an operational perspective Ethos has been a valuable addition to The Ice Co Storage & Logistics’ operations toolkit. The client has now continuous access to view the plant’s operating parameters through the Ethos dashboard on a web portal. Operations regularly log in to the online portal to assess the plant conditions from their laptop or phone. In this way, the customer is notified by Monday morning emails of irregular plant behaviour and take pre-emptive steps to address potential issues before they can effect a plant failure.

Ethos has the unique ability to assess not just how well the plant is currently performing, but can also map those parameters against how it should ideally be operating and quantifies the gap between the two in intelligible terms. It is also capable of providing actionable insights into how that gap can be decreased, thus achieving practical optimisation and maximising efficiency. Able to adapt to the constantly changing parameters of a dynamic refrigeration environment, Ethos is adept at assessing system efficiency, regardless of how conditions and load may vary from day to day. In recognition of these capabilities, Ethos was recently awarded 2018 Refrigeration Product of the Year.

Since the system’s installation, Star have established an even closer partnership with The Ice Co, securing a national maintenance contract across its ice manufacturing as well as its cold storage businesses, rolling out Ethos across all of the company’s facilities.

Star’s continual support in identifying and delivering the solutions that are best for their customers has led to the development of a trustworthy partnership which is the key to helping The Ice Co Storage and Logistics fulfil its logistically complex obligations to its customers nationwide.

- Energy Management